Achieving Operational Excellence and Designing a Customer Delivery System

This session, based on the Shingo award-winning book Design for Operational Excellence: A Breakthrough Strategy for Business Growth, sets the framework for organization-wide transformations. Instead of industry jargon, it explains in practical terms how to develop an operation that delivers on time day in and day out. Rather than looking to eliminate waste through continuous improvement, participants learn to use proven guidelines to create a customer delivery system that works seamlessly even in complex manufacturing environments. The result is on-time delivery without the need for meetings, expedites, or management intervention.

Who Should Attend

Individuals leading or participating in lean, continuous improvement, or OpEx initiatives in their organization. Companies in all industries will benefit from this executive-level course, including manufacturers and service organizations.

How to Enroll

| Type | Duration | Course Overview | Info/Details | |

|---|---|---|---|---|

| Private Training | 4-6 Hours | Our experts teach the strategy behind OpEx to individuals who will drive the transformation, including executives, managers, and supervisors | $$$$$ | Learn More |

| Open Enrollment Training Event | 2 Hours | Attendees from all industries and job functions participate in this open enrollment event | $$$ | Learn More |

| Online | Unavailable | |||

| Webinar | 1 Hour | A brief overview of the concepts taught in the full-length course. Check our upcoming webinars for "High-Performance Operations: How They Work." | FREE | Learn More |

Related Whitepapers

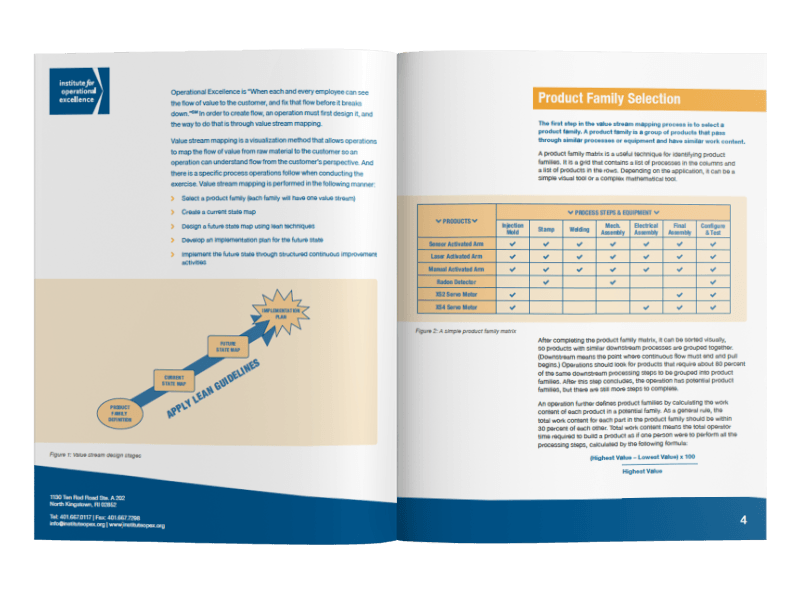

End-to-End Value Stream Design

(also known as Value Stream Mapping)

This introductory workshop teaches how to design a value stream that utilizes flow to achieve Operational Excellence. Through the use of a current state map, the workshop allows participants to see the flow of value to the customer. From there, the workshop will cover how to construct a future state map to build a lean flow, the first step towards Operational Excellence, using guidelines such as takt, finished goods strategy, continuous flow, FIFO, pull, scheduling one point, interval scheduling, and pitch. The workshop concludes with outlining the beginning steps of an implementation plan.

Who Should Attend

Manufacturing professionals looking for skills on how to design an accurate future state map using design principles.

How to Enroll

| Type | Duration | Course Overview | Info/Details | |

|---|---|---|---|---|

| Private Training | 3.5 Days | Our coaches guide a client’s internal team to build a company’s current and future state value stream map using the firm’s product and processes | $$$$$ | Learn More |

| Open Enrollment Training Event | 4 Hours | Participants in this public training event learn the academic principles of value stream mapping using case studies and exercises | $$$ | Learn More |

| Online | Unavailable | |||

| Webinar | 1 Hour | A brief overview of the concepts taught in the full-length course. Check our upcoming webinars for "Value Stream Mapping Tune-Up." | FREE | Learn More |

Related White Papers

Creating Mixed Model Value Streams

This advanced course takes the concepts of value stream design to the next level by teaching participants the method for creating flow in factories that have a high complexity of products, demand, and shared resources.

By understanding product family selection and how to apply lean principles in high-variety environments, students will learn how to create a value stream of multiple product flows at the pull of the customer. Attendees will also learn how to design and schedule the pacemaker process for value stream flow in these complex operations.

Who Should Attend

Manufacturing professionals, including operations, engineering, and lean managers looking for advanced techniques to create flow through complex factories with varying demand and high product mix.

How to Enroll

| Type | Duration | Course Overview | Info/Details | |

|---|---|---|---|---|

| Private Training | 1.5 or 3 days (if bundled with Shared Resources) | Our trainers lead the client’s internal team in creating product families, establishing pitch, and calculating takt time as well as other technical concepts needed to build their future state value stream map | $$$$$ | Learn More |

| Open Enrollment Training Event | 8 Hours | Professionals from all industries attend this open enrollment event that teaches the academic principles to create mixed model flow using case studies and exercises | $$$ | Learn More |

| Online | 2 Hours | This self-paced course covers the same academic principles as our live training in an interactive format | $ | Learn More |

| Webinar | 1 Hour | A brief overview of the concepts taught in the full-length course. Check our upcoming webinars for "Mastering Flow with High Product Mixes and Unpredictable Demand." | FREE | Learn More |

Related White Papers

Creating Flow Through Shared Resources

In this technical class for manufacturers, participants delve into the newest techniques to implement flow that achieves Operational Excellence in the difficult and complex environment of shared resources.

The class covers the difference between product families and process families along with various FIFO techniques such as sequenced FIFO and offset scheduling. It also addresses advanced concepts like balancing flow at shared resources. Attendees will leave prepared to create flow for custom component build to supply downstream assembly or customers the parts they need, when they need them.

Who This Course is For

Manufacturing professionals, including lean managers and those in operations and engineering looking for advanced techniques to create flow through complex factories with shared resources.

How to Enroll

| Type | Duration | Course Overview | Info/Details | |

|---|---|---|---|---|

| Private Training | 3 days (must be bundled with Creating Mixed Model Value Streams) | Our facilitators work with a team to build a future state value stream map for environments with shared resources | $$$$$ | Learn More |

| Open Enrollment Training Event | 8 Hours | Attendees from all industries participate in this open enrollment event that teaches the academic principles to straighten spaghetti flow | $$$ | Learn More |

| Online | Unavailable | |||

| Webinar | 1 Hour | A brief overview of the concepts taught in the full-length course. Check our upcoming webinars for "Untangling Flow in Shared Resources, Monument Equipment, and Job Shops." | FREE | Learn More |

Related White Papers

Operational Excellence in the Office

(also known as Business Process Value Streams)

In this class, participants learn the concepts and skills to create lean value streams in office processes. The session explains how to apply in-depth principles such as process family matrices, binary connections and workflow cycles, integration events, pitch, and other techniques to create lean value streams that support Operational Excellence.

Participants will learn how to create flow in office environments, design processes for seeing when flow has stopped, and develop methods for regaining flow without management.

Who Should Attend

Anyone seeking to improve operations in office environments such as sales, finance, human resources, engineering, and more. Companies in all service industries, as well as manufacturers seeking to improve their office functions, will benefit from this course.

How to Enroll

| Type | Duration | Course Overview | Info/Details | |

|---|---|---|---|---|

| Private Training | 3.5 Days | Our coaches work with a team to build a company’s current and future state value stream maps using the firm’s products and processes | $$$$$ | Learn More |

| Open Enrollment Training Event | 1 Day | Attendees from all industries participate in this public workshop that teaches the principles to streamline business processes | $$$ | Learn More |

| Online | 3 Hours | This self-paced course covers the same academic principles as our live event in an interactive format | $ | Learn More |

| Webinar | 1 Hour | A brief overview of the concepts taught in the full-length course. Check our upcoming webinars for "Developing a High-Performance Office with Operational Excellence." | FREE | Learn More |