One of the most important questions that needs to be answered in any operation striving for Operational Excellence is, “How does each process (or person) know what to work on next?” While this question may seem easy to answer, it can pose challenges to operations of all complexity and in every industry.

The reason this question can be so challenging to answer is that it represents the point in an operation where the flow of information must be matched up with the flow of material. Any discontinuity between these two flows will result in someone on the product floor either not knowing what they should work on next (if there is a break in the information flow), or not being able to do so (if there is a break in the flow of material).

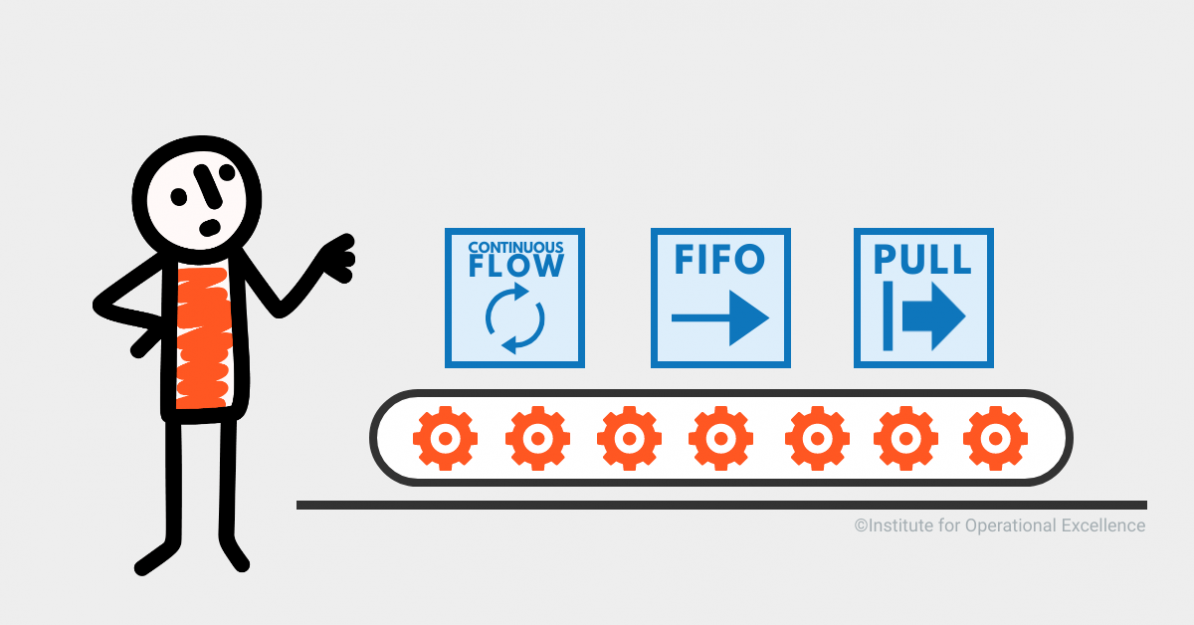

Continuous flow, FIFO, and pull are three of the eight lean guidelines and seek to answer the question of “How does each process (or person) know what to work on next?” without requiring the involvement of management. The way they succeed in doing this is by bringing together in a seamless way the information flow through a facility with the corresponding material flow.

Continuous Flow – Make One, Move One

Want to Read More?

Log in or register to continue reading this article.