Adhesives and sealants manufacturers face unique

challenges compared to other industries when undergoing lean or continuous improvement initiatives, including chemical reactions, vessels, batch sizes, curing times, and many more. None of these issues are addressed by the lean techniques that grew from the automotive industry. So how can this industry create flow in its high-variety, complex environments? To start, operations must take a different approach to continuous improvement itself.

Articles

Creating Pitch in the Office

Pitch is an important component of a future state value stream implementation in an office environment – but it can also prove challenging. The answer is to understand the purpose of pitch and then design pitch that works within a specific office. Learn four key concepts to make pitch effective in your office.

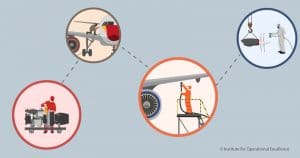

Practical Tips for Mapping Value Streams in MRO Operations

Value stream mapping in an MRO isn’t straightforward due to the high amount of variation that exists. Learn 8 steps to create an accurate design for the most value.

Practical Tips for Mapping Value Streams in MRO OperationsRead More

Operational Excellence and Lean: What’s the Difference?

OpEx and lean share some similarities in their methodologies, but there are key differences. Lean focuses on eliminating waste and does this by training people on tools that eliminate waste. In Operational Excellence, the focus is on business growth, not waste elimination.

Operational Excellence and Lean: What’s the Difference?Read More

FAQs on Designing Product Families for Mixed Model Production

Understand common obstacles to creating product families for mixed model production and how to overcome them.

FAQs on Designing Product Families for Mixed Model ProductionRead More

How to Make Flow Visual

Achieving Operational Excellence is dependent on every employee being able to “see” how the processes are connected. Learn how to implement a robust system of visuals to drive business growth.

Managing Intervals for OpEx

Learn how setting a destination of Operational Excellence produces significant gains in both operational and financial results in months, rather than an “endless journey” of continuous improvement.

FAQs: Topics on OpEx in the Office – Part Two

In this article, we will be exploring questions on Technology, R&D and Management Push Back. Part two of the Office OpEx FAQ two-part series.

Three Real OpEx in the Office Questions, Answered by Our Experts

This article answers questions on complicated office value streams, the OpEx mindset and more, submitted from attendees of our recent webinar, Operational Excellence in the Office.

Three Real OpEx in the Office Questions, Answered by Our ExpertsRead More

FAQs: Topics on OpEx in the Office – Part One

In this article, we will be exploring questions on Takt capability, integration events, sequencing, pull flow and more.

How to Flow Information through Finance and Accounting Departments

From our Ask an Expert column in the Quarter Two, 2016 IOE Member Newsletter.

How to Flow Information through Finance and Accounting DepartmentsRead More

Applying OpEx in Multiple, Virtual and Dispersed Office Locations

How can you ensure consistent, predictable results in the office when it is consists of multiple locations or virtual employees who work remotely? Workflow cycles are the answer. Learn why workflow cycles are a game changer and how to implement them in dispersed environments for a repeatable, predictable flow of information.

Applying OpEx in Multiple, Virtual and Dispersed Office LocationsRead More

What are the Benefits of Operational Excellence?

Read case studies on Operational Excellence and how training on the principles of OpEx enabled these companies achieve OpEx.

Emails, Meetings and Unpredictability in the Office: How Operational Excellence Can Help

Learn how applying the same principles of Operational Excellence used in production can have significant performance benefits for any office environment struggling with email overload, time-wasting meetings and unpredictable workloads.

Emails, Meetings and Unpredictability in the Office: How Operational Excellence Can HelpRead More

Using FIFO in Your Lean Office

FIFO is critical to connecting process flow, preserving the sequence of work between processes, and limiting how much work can be between processes at any given time. Learn how to overcome certain challenges in the office when using FIFO.